PWR vessel internals are essential for core support, coolant flow control, and neutron shielding. Their lifetime critically affects plant operation due to the complexity and cost of replacement.

Lower internals near the core (e.g., core barrel, baffles, bolts) face high neutron flux, causing hardening, loss of ductility, creep, IASCC, and swelling. These ageing mechanisms challenge long-term operation.

Upper internals, such as Control Rod Guide Assemblies, suffer wear that may block control rod movement and increase maintenance costs. Additionally, wear of cobalt-based clevis inserts raises dosimetry concerns and may compromise control rod insertion if tolerances are exceeded.

What is VIP?

The VIP project aims to improve understanding and prediction of degradation mechanisms in PWR internals, based on failure feedback. It focuses on SCC, IASCC, and mechanical wear. Four objectives structure the project:

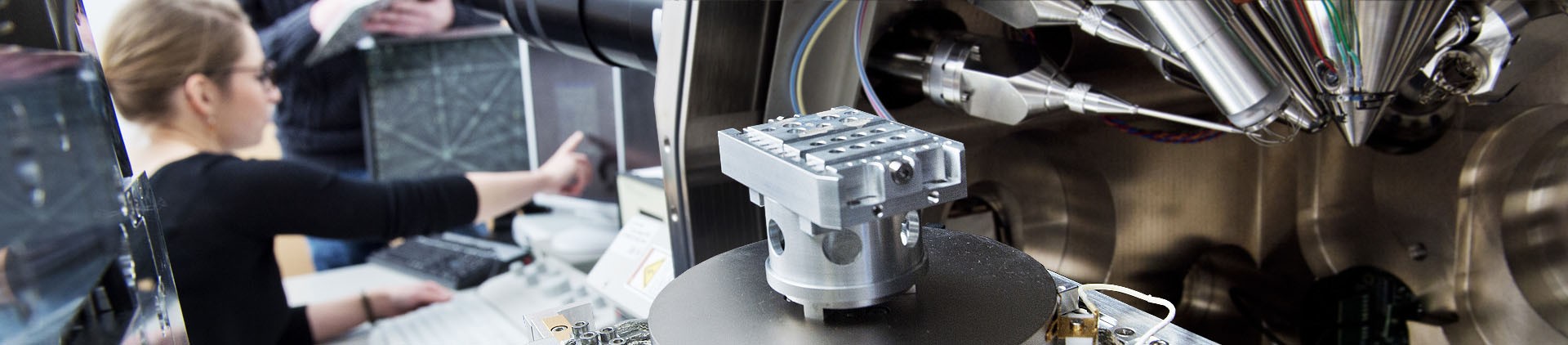

- Experimental data acquisition using SEM, TEM, APT, mechanical tests, and (IA)SCC testing.

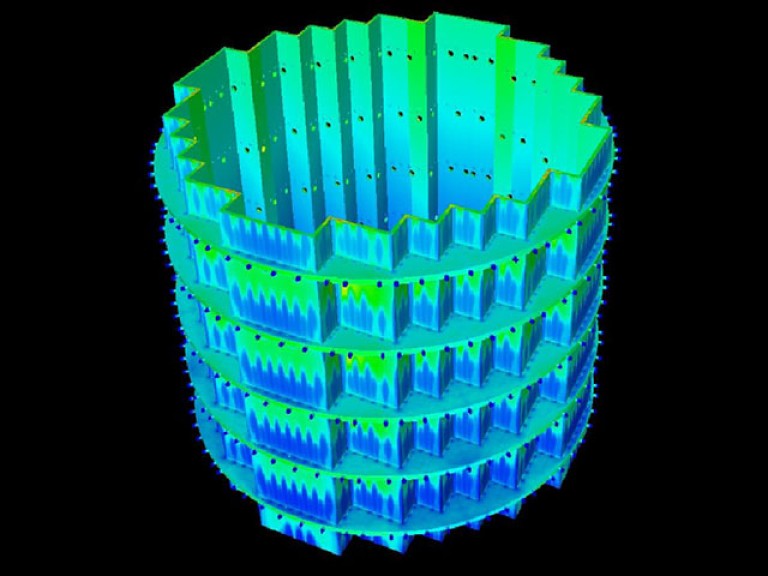

- Multi-scale modeling and loading simulations to predict microstructure evolution and mechanical behavior.

- Irradiation damage control, proposing monitoring and mitigation strategies for lower internals.

- Wear damage control, with experimental tests and wear rate predictions for guide cards, sleeves, and clevis inserts.

The VIP project enhances understanding of degradation in irradiated reactor internals. It provides experimental data and modeling tools to predict SCC, IASCC, and wear, improving safety and reliability. Insights support lifetime assessments, failure prevention, and optimized maintenance strategies for key components in high-radiation environments.