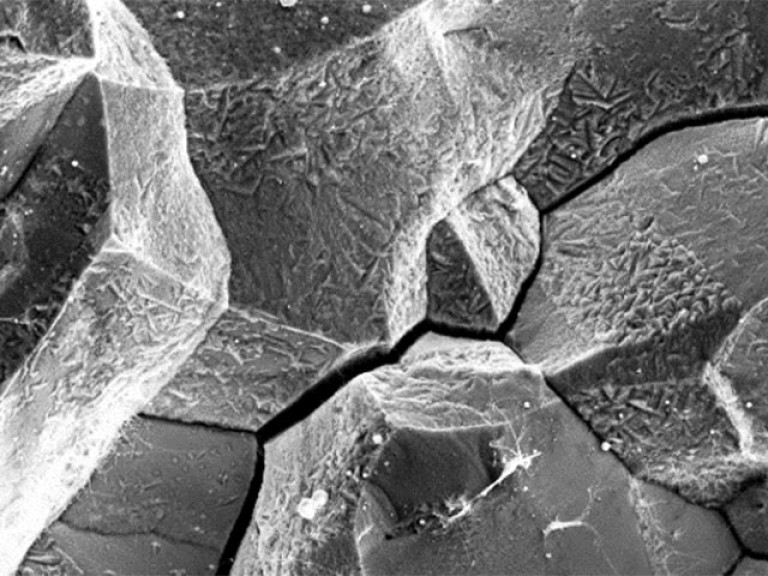

Primary Water Stress Corrosion Cracking (PWSCC) is a long-standing issue in nuclear power plants, affecting several austenitic alloy components.

Cracks found in French units Civaux 1 and Penly 1 highlight the role of strain hardening and tensile stress in 316L pipes. These events raise safety and cost concerns due to inspections, repairs, and lifetime management.

Predictive tools are essential to anticipate SCC evolution and support risk-based decisions. A physics-based engineering models has been developed to replace empirical approaches, focusing on SCC in stainless steels and nickel-based alloys, with potential adaptability to other material/environment pairs.

What is CSI?

The CSI project aims to improve the reliability of stress corrosion cracking (SCC) predictions for nuclear components by addressing key industrial challenges through four main objectives:

- Improve SCC susceptibility modeling: Extend model validity, generalize initiation models, and understand crack growth and coalescence.

- Model microstructural effects: Account for machining, welding, inclusions, and material interfaces.

- Enhance CODE_CORIOLIS: Add time-dependent features, database integration, training, and collaborative use cases.

- Predict IGSCC in 316L stainless steel: Refine initiation/growth models, assess environmental and loading effects, evaluate zinc injection benefits, and study SCC–thermal fatigue interactions.

The CSI project will deliver quantitative, operational models and a digital tool capable of predicting complete PWSCC scenarios in 3D-modeled laboratory specimens or industrial components. These deliverables will enable end-users to perform rapid and reliable evaluations of SCC risks in primary circuit components.

They will be used by engineering teams to:

- Better explain observed degradation and anticipate future occurrences.

- Optimize inspection frequencies to reduce costs linked to preventive replacements.

- Select appropriate mitigation strategies to extend component lifetime.