The MANDENA4 project combines two sub-projects: A3D, focused on 3D finite element modeling of ultrasonic testing, and Eddy Current signal recognition using machine learning.

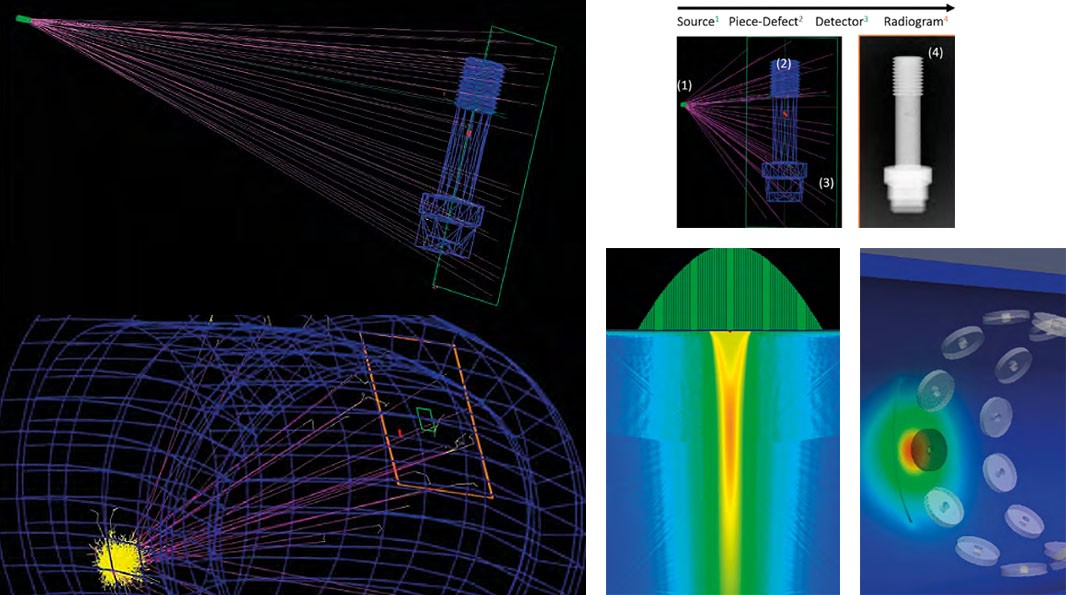

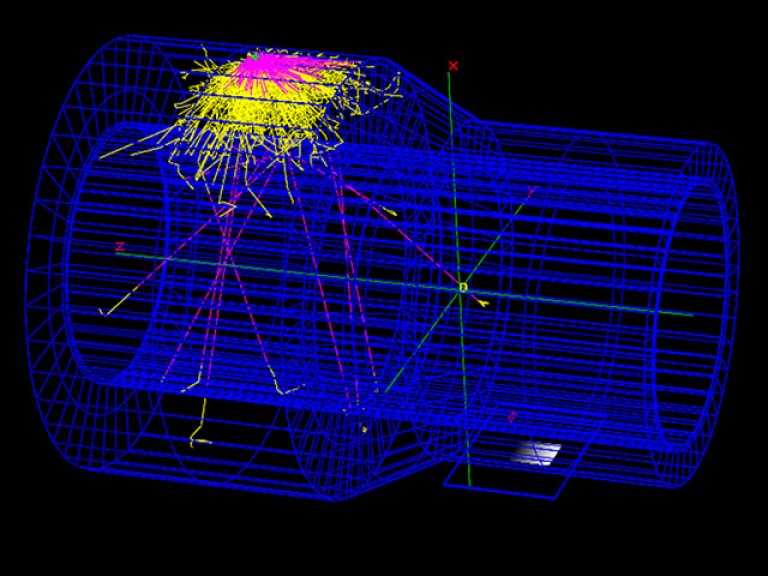

A3D simulates complex geometries and heterogeneous materials using advanced meshing and boundary conditions. MANDENA enhances A3D with a wider transducer library and better mesh/time-step handling, aiming to deliver validated, high-fidelity UT simulations for industrial use.

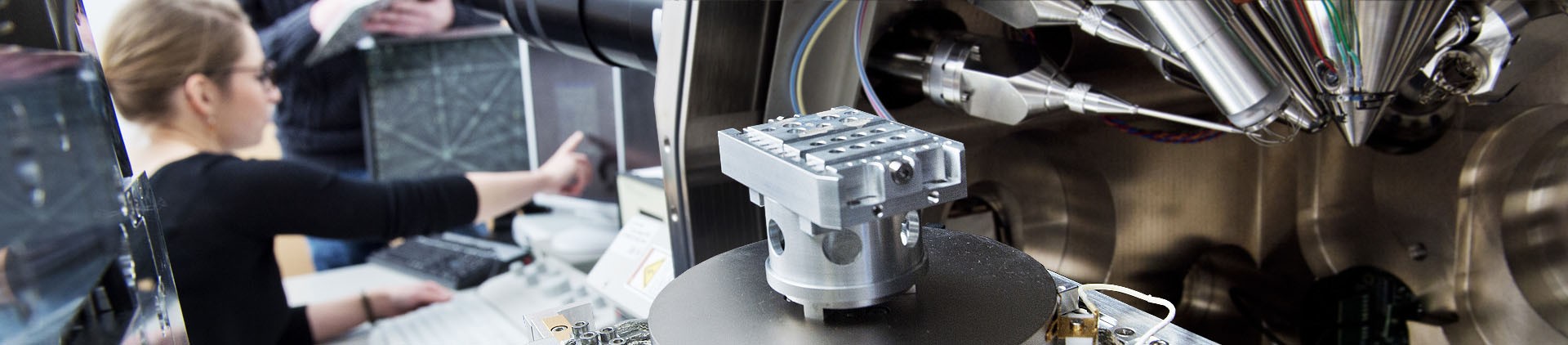

Steam generators are critical components in nuclear power plants, but their heat exchanger tubes are prone to various degradation mechanisms, increasing the risk of leakage. To overcome the limitations of manual and rule-based eddy current data analysis, a machine learning-based approach is proposed to improve detection reliability and reduce false alarms.

What is MANDENA?

A3D

Improved versions will be released during the project, integrating feedback from MAI members. The 4 phases include:

- identifying configurations,

- mesh impact studies,

- complex geometries with homogeneous materials,

- heterogeneous materials like welds.

The goal is to deliver validated, high-fidelity UT simulations for industrial applications.

Eddy Current signal

The project applies guided machine learning to in-service eddy current data. It follows three steps:

- training with known data (Open Test),

- blind evaluation (Blind Test),

- iterative optimization.

The final goal is intelligent signal recognition algorithms, assessed for efficiency and reliability via probability of detection.

MANDENA improves UT modeling and EC signal analysis, enabling accurate, validated simulations, reduced false alarms, efficient batch processing, and scalable tools for nuclear inspections.