Additive Manufacturing (AM) of metallic materials, supported by powder metallurgy advances, offers new opportunities for component design, production, and repair in nuclear and energy sectors.

To assess its industrial relevance, focus is placed on component quality (homogeneity, ageing behavior) and process benefits (shorter lead times, obsolescence management).

Key challenges include understanding AM microstructure effects on ageing (fatigue, corrosion, irradiation), influence of raw materials and process parameters, need for post-treatments, adaptation of NDT methods, and resistance assessments. The goal is to qualify and codify AM for safety-critical applications.

What is AMP?

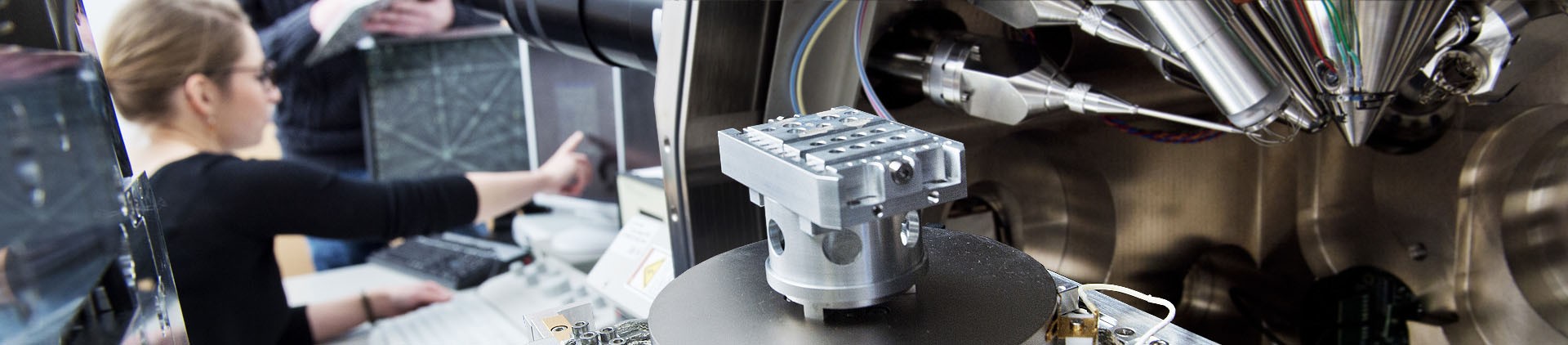

This MAI project explores several additive manufacturing (AM) technologies, each with specific applications and challenges. It includes:

- Cold Spray for solid-state metal powder deposition,

- DED processes like LMD and WAAM for part repair and large component fabrication,

- LPBF/SLM for small precision parts,

- HIP for densifying and finishing critical components.

This project supports the integration of additive manufacturing into nuclear codes by providing data on ageing behavior. It aims to:

- improve material quality (homogeneity, near-net shape),

- optimize maintenance (manage obsolescence, reduce lead times),

- enhance performance through better component design and use of functional gradient materials.

Cold Spray

Making metal deposits by projecting powder at very high speed. This additive manufacturing process is used for applications to repair damaged parts or build coatings.