To improve fundamental knowledge on material aging, state of the art experimental facilities are necessary. Have a look on some experimental works performed in MAI members’ facilities.

EDF facilities

Mechanical Lab

Characterizing the mechanical properties of materials (tensile, resilience, toughness, fatigue, creep) and carrying out tests on components to provide optimal characteristics and methods for the mechanical justification of components.

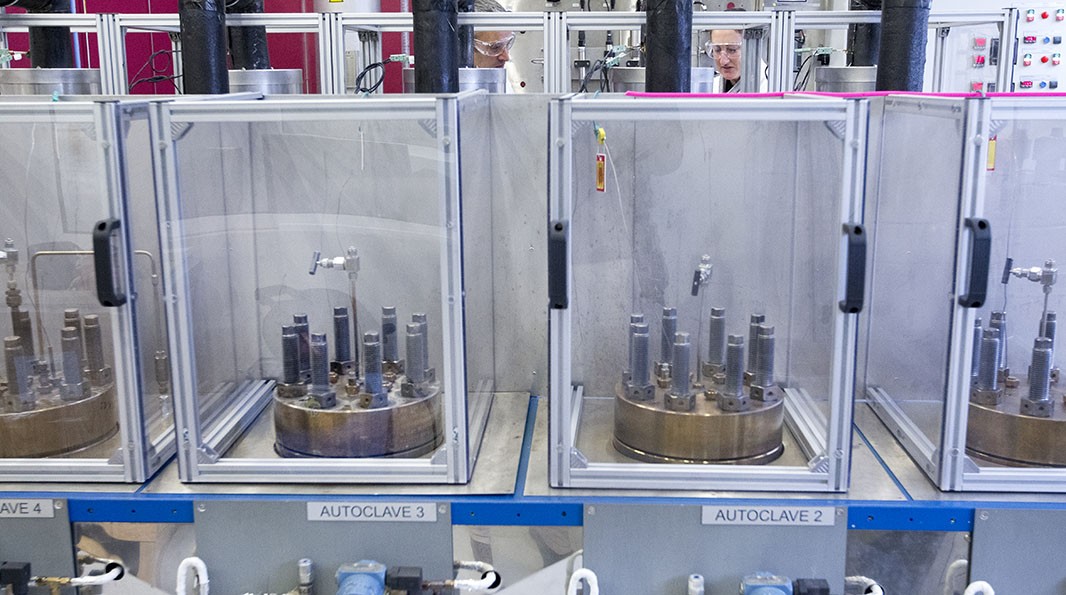

Corrosion Lab

Understanding and simulating stress corrosion degradation phenomena of nuclear power plant primary circuit components.

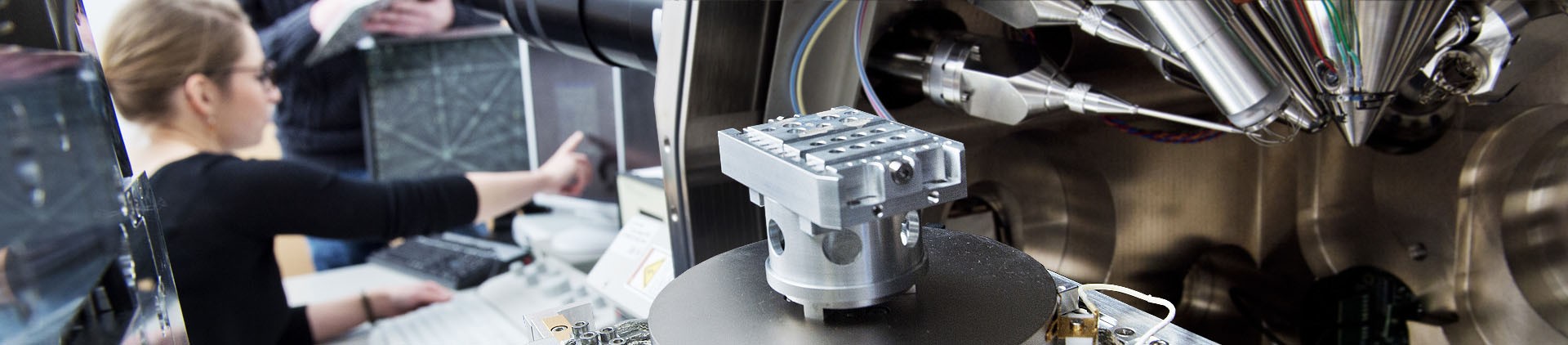

Microscopy Lab

Understanding the aging of materials by focusing on the microstructure and local chemical composition of materials by electronic microscopy.

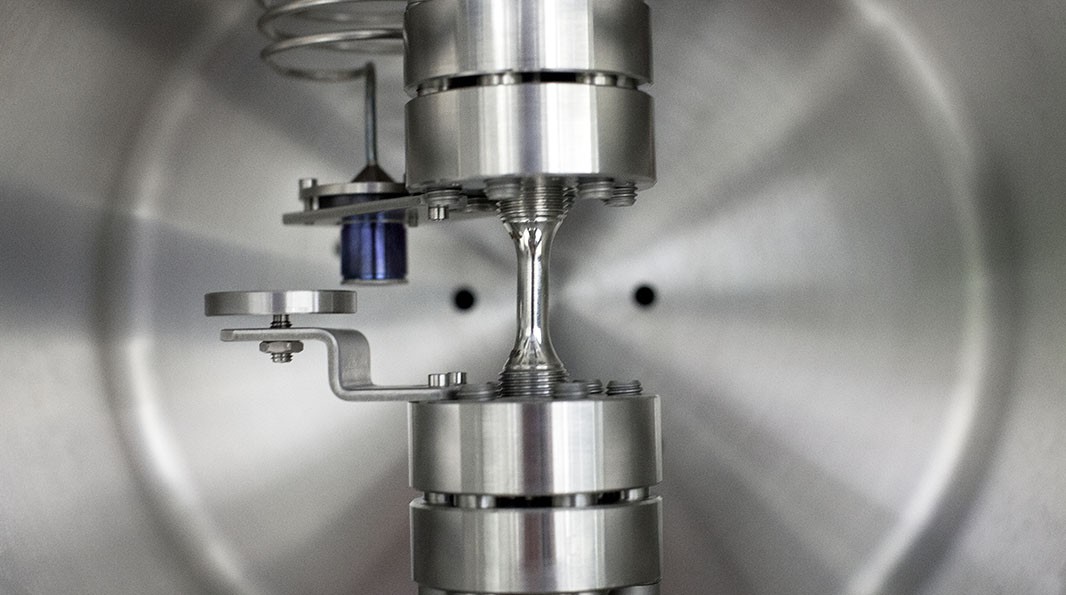

FATCOR

Studying the fatigue and corrosion properties of nuclear reactor materials in the primary environment.

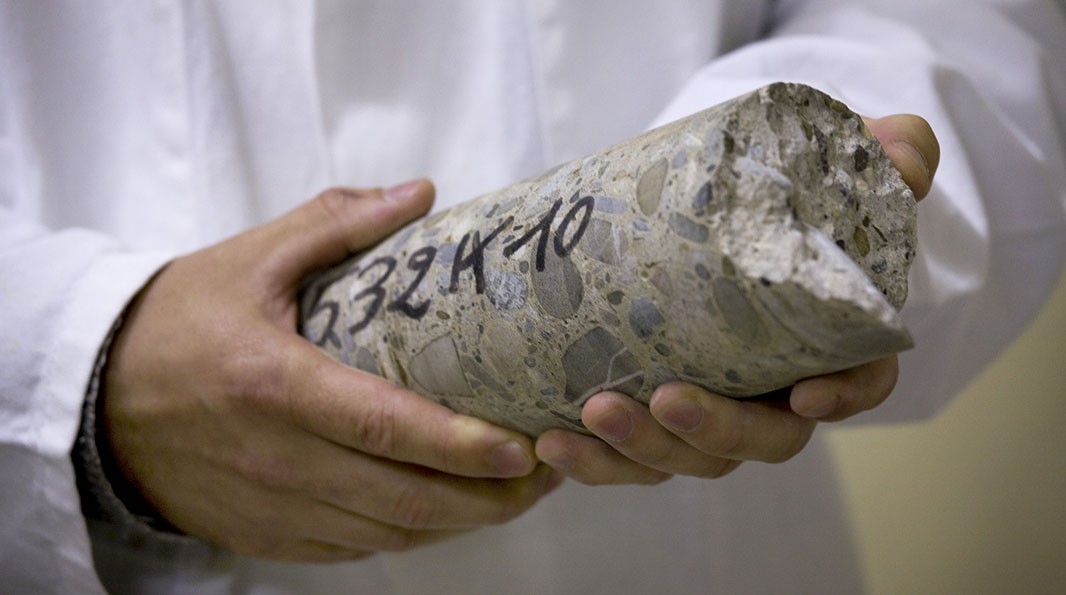

VERCORS

Studying in an accelerated way the concrete's behavior and the structure of the inner containment of a reactor building, in particular its aging, its deformation and its sealing.

Civil Engineering Lab

Understanding the evolution and aging of Civil Engineering materials, to optimize the maintenance strategy for Civil Engineering works in the nuclear, wind, hydraulic and downstream generating fleet.

ENERGIE Loop

Carrying out studies to identify the fouling mechanisms of pressurized water power plant steam generators and defining the kinetics of deposit formation under different operating conditions.

Cold Spray Lab

Making metal deposits by projecting powder at very high speed. This additive manufacturing process is used for applications to repair damaged parts or build coatings.

Welding Lab

Achieving models in order to study and understand the links between process, metallurgy, defects and final mechanical properties, with the aim of facilitating and making reliable future manufacturing. This installation is equipped with three welding machines as well as two test benches for the study of sensitivity to cracking during welding.

Non-Destructive Testing Lab

Focus on ultrasonic inspection: understanding physical effects, qualifying processes, studying metallurgical impacts, analyzing complex materials, and developing advanced testing methods.

Polymer Lab

Focus on polymer ageing: experimental studies, service-life monitoring, lifespan modeling, and testing of cables, pipes, paints, and coatings under controlled thermal, chemical, and mechanical conditions.