Nuclear - 50 years and the future awaits

OPERATIONAL PERIOD

The operational life of nuclear power stations is a key issue for the EDF Group and, therefore, for its R&D.

Research into materials in particular is an essential activity in the operational life of nuclear power plants. Every material reacts differently over time, to the climate etc.

Controlling these parameters is essential to meet the major challenges of energy production: safety and availability of installations, performance, etc.

Join us and discover the major research projects conducted by EDF R&D on their test sites.

Transcription

Materials Research : how R&D is combating power station ageing

Nuclear power plants are made up of a vast array of materials. One of the key roles of EDF’s R&D is to anticipate and manage the effects of time on these various materials. The goal: to predict and ensure the availability and safety of the facilities, while optimizing their performance.

Discover how our researchers are anticipating the future of nuclear power plants by studying the different materials that make them up.

Your browser does not support javascript.

To enable you to access the information, we suggest you view the video Materials Research : how R&D is combating power station ageing in a new tab.

[This animated film shows how EDF R&D studies materials to anticipate the aging of components in the nuclear fleet and prepare tomorrow’s maintenance thanks to innovative technologies such as additive manufacturing.]

Materials

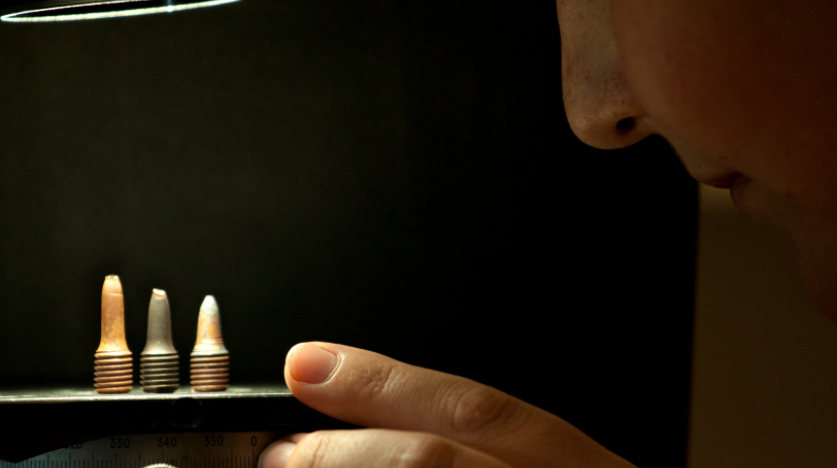

Maintaining power plants requires knowing as precisely as possible the operating life of components, so they can be repaired or replaced before failure. These components are highly diverse in nature and made from a wide range of materials.

Drawing on its expertise in civil engineering, metallurgy, and chemistry, R&D tests steel fatigue, part corrosion, and tube fouling.

It develops generic tools to deepen its knowledge and address the aging and alterations affecting the generation fleet.

And what about components that cannot be replaced, such as the reactor vessel and the containment building? Through both digital tools and experimental testing—carried out in our laboratories and on dedicated facilities—R&D refines its understanding and can predict the behavior of these two components.

Regularly consulted by the Nuclear Safety Authority, EDF relies on the knowledge and studies conducted by R&D to provide responses and justify the integrity of reactor vessels and containments.

And tomorrow?

R&D is also preparing for the maintenance of the future by exploring new manufacturing methods such as additive manufacturing. Also known as 3D printing, it makes it possible to create a physical object layer by layer by adding material from a digital file.

This new method will bring many advantages, such as producing spare parts more quickly when suppliers are scarce, or repairing certain components by replacing only the damaged part instead of the entire component.

In the long run, additive manufacturing could help us change how we design new components, enhancing their performance.

R&D therefore has a central role to play when it comes to materials. It develops expertise and knowledge on the current nuclear fleet to support its maintenance and safety objectives, while also exploring new manufacturing methods and the nuclear technologies of tomorrow.

The Vercors Laboratory : R&D resists!

Discover Vercors, a site where EDF R&D tests the resistance of nuclear facilities. Or, more precisely, the effect of time and activity on nuclear reactor confinement structures, using a maquette. Fascinating, isn’t it? Wait for the next bit!

Interview : how the EDF Group sees the future of its nuclear power stations

The Grand Carénage (major refit) is a major industrial nuclear programme led by the EDF Group. It aims to modernise and renovate all of our nuclear power plants with all the players involved, in order to extend the life of the facilities in complete safely.

Find out more in a fascinating joint interview with two experts from EDF R&D.