Nuclear risks: focus on prevention

Nuclear power plant safety is a top priority for EDF and the public authorities to ensure that their operation does not affect people or the environment.

Successive lines of defence to ensure the safe operation of nuclear facilities

Nuclear safety involves the full set of measures adopted, from the design of the power plant through its construction, operation and final decommissioning, to ensure that radioactive products are not released to the environment.

Accident prevention is based on the “defence in depth” concept. This consists in systematically addressing potential technical failures and human error by setting up successive lines of defence: safety systems, procedures, technical and administrative controls.

The defence in depth concept has a triple focus:

- Prevention, designed to avoid failure

- Monitoring, to anticipate failure or detect it immediately

- Action to limit the consequences of a failure

These principles govern the operation of a power plant and can entail automatic or manual action. If an event occurs that exceeds “normal” operation, automatic systems respond very quickly to restore normal reactor operation. In parallel, operators receive real-time information enabling them to take action if necessary. These automatic and manual actions are part of the power plant monitoring system.

Safety mechanisms have been included in the power plant design to respond to possible human error and incidents. For example, the “control clusters” used by operators to adjust electricity generation will automatically drop if an abnormal situation occurs, shutting down the reactor within a few seconds.

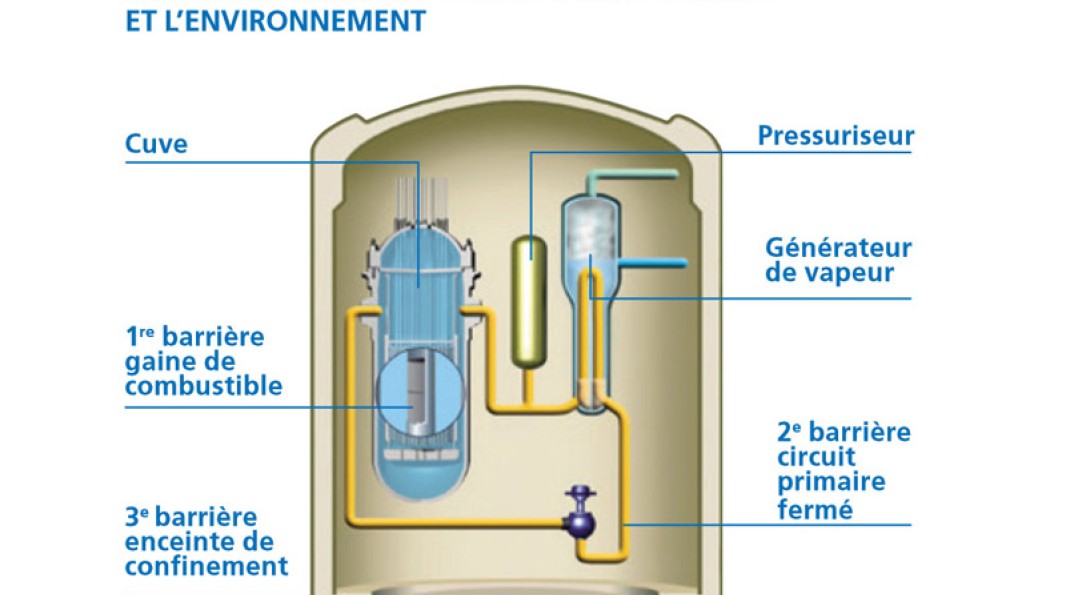

Three safety barriers between the fuel and the environment

The defence in depth principle also entails installation of successive physical barriers to prevent radioactive products from escaping to the environment:

- The wall of tubes (“rods”) containing the enriched uranium pellets in each fuel assembly

- The steel envelope that constitutes the primary circuit of the power plant (the fluids flowing in it are radioactive)

- The concrete containment that encases the primary circuit

THREE SAFETY BARRIERS BETWEEN THE FUEL AND THE ENVIRONMENT

Vessel Pressuriser

1st barrier Fuel rod cladding Steam generator

3rd barrier containment 2nd barrier closed primary circuit

Emergency drills are regularly held for the teams working on site. Every year, at each nuclear power plant, seven or eight accident simulation drills are organised to train teams to respond to the full range of situations. Reactor operators also take a six-week training course every year.

Following the accident at the Fukushima power plant in Japan, EDF proposed that this system be expanded by:

- Reinforcing the systems used to protect nuclear facilities from earthquake and flooding, with the addition of alternative power and water supply systems

- Creating a nuclear rapid response force (FARN) made up of 300 people with the capacity to respond at all nuclear power plants in France within 24 hours.

Your browser does not support javascript.

To enable you to access the information, we suggest you view the video in a new tab.

Prevention, monitoring, safety barriers, emergency drills: based on international lessons learnt, the Group is adopting an increasing number of measures to prevent accidents and ensure the best possible level of safety at its power plants.

Your browser does not support javascript.

To enable you to access the information, we suggest you view the video in a new tab.