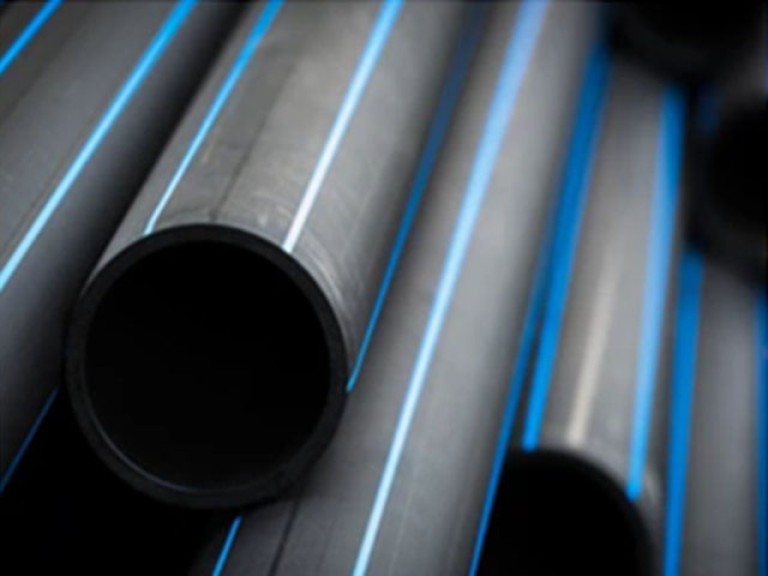

High-Density Polyethylene (HDPE) pipes are used for buried cooling systems due to their seismic resistance and long-term durability. HDPE offers strong mechanical and corrosion resistance, ease of installation, and maintenance.

Research focuses on understanding chemical and mechanical aging under operating conditions (10 bar pressure, biocide-treated water). The goal is to model degradation mechanisms for current and future systems.

While HDPE aging in air and fresh water is well documented, aging in chlorinated environments, especially with hypochlorous acid, and chemical/mechanical coupling remains underexplored.

What is HDPE pipes?

This MAI project focuses on 4 different objectives:

- defining accelerated ageing conditions close to real operating environments,

- identifying ageing mechanisms and their impact on mechanical properties,

- extrapolating results from material to structural scale,

- conducting ageing tests on full-scale structures via representative test loops.

Compared to metal pipes in concrete galleries, HDPE offers a significant cost saving. These activities include state-of-the-art reviews, test facility design, material characterization, ageing tests in chlorinated water and seawater, and predictive modeling through a thesis and failure analysis reports.

These outputs will secure the projected savings and ensure reliable long-term performance of HDPE piping systems.