Expertise in the nuclear fuel cycle, from mining to recycling

A great variety of operations are required to supply nuclear power plants with fuel, including uranium extraction, processing and transport and spent fuel re-processing and recycling. EDF’s fuel cycle capabilities are supported by a network of safe, efficient, long-term industrial partners.

Uranium extraction and fuel production

As the depletion of fossil fuels puts pressure on the energy sector, nuclear power provides a sustainable response. Uranium production is ensured for a minimum of 100 years, according to the OECD’s Nuclear Energy Agency (NEA). In addition, uranium deposits are not in the hands of a limited number of countries with a virtual monopoly but instead are spread across all the world’s regions, including areas that are geopolitically highly stable.

To secure supplies of natural uranium, EDF procures it from a variety of mining operators in a number of countries, including Niger, Kazakhstan, Canada and Australia.

Natural uranium is an ore that is extracted from both underground and open-cast mines. It is present in the earth’s crust as a mixture of uranium 238 and uranium 235 (which accounts for 0.7%). Only uranium 235 can be used as a fuel in current reactors. Once the crude uranium has been mined, it must be processed and then enriched to increase the concentration of uranium 235.

To carry out the various steps involved in enriching uranium, EDF works with a variety of industrial partners such as the French group AREVA and companies such as Urenco (UK, Germany and Netherlands), Tenex (Russia) and USEC (United States).

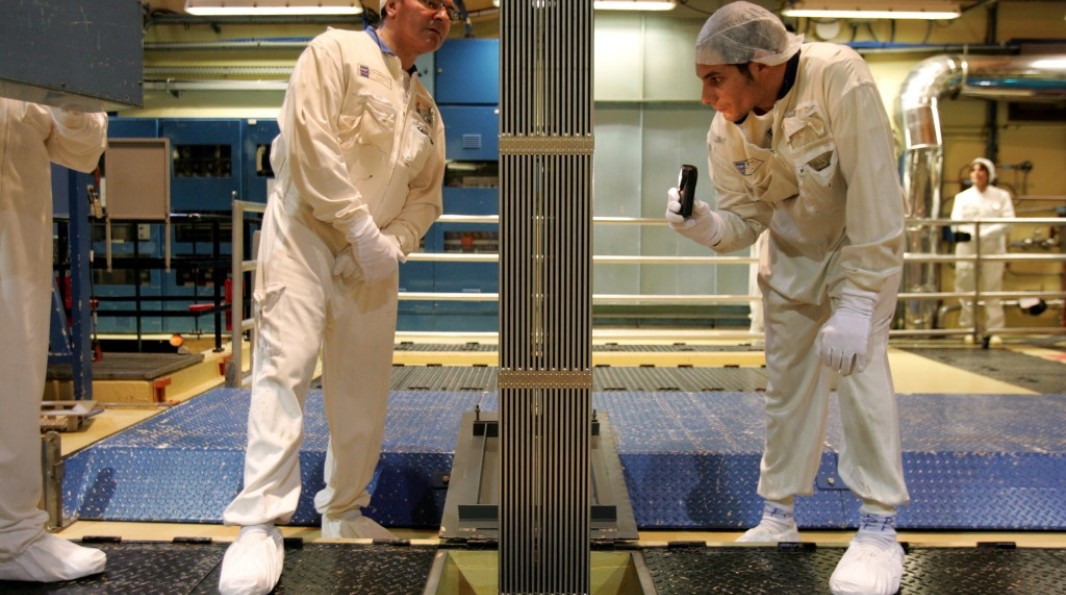

Enriched uranium is then compacted into pellets. These are placed in sealed zirconium alloy tubes known as rods. The rods are “assembled” into bundles of 264 to form a fuel assembly. This contains about 500 kg of uranium and is designed to withstand the very high mechanical, hydraulic, thermal and neutron forces in the reactor core. They are the reactor’s first safety barrier. Their reliability is therefore a major goal for nuclear operators.

The French AREVA Group and the US Westinghouse Electric Company are the main manufacturers of nuclear fuel assemblies and EDF’s two suppliers to date.

Your browser does not support javascript.

To enable you to access the information, we suggest you view the video in a new tab.

Transport to the reactor core

The fuel assemblies are transported by road or rail. The assemblies have low radioactivity until they are used and no particular radiation protection is required when handling them.

The assemblies are then placed in the reactor core, where they remain for three to four years, after which they gradually become spent. They are then withdrawn from the reactor.

Spent fuel is a mixture of uranium and plutonium and is highly radioactive. It nevertheless contains high potential energy at this stage and is put into intermediate storage in cooling ponds for three years prior to recycling.

The fuel load required by a 900 MW reactor is 157 “assemblies” containing a total of 11 million pellets of enriched uranium

A new lease on life for spent fuel

Once cooled, the spent fuel is transported to AREVA’s La Hague reprocessing plant in northern France. Re-usable materials (plutonium and depleted uranium) and final waste are separated.

The separated plutonium is blended with uranium oxide to create a new fuel, MOX (Mixed Oxide Fuel), which can again be used in a nuclear power plant. AREVA’s Melox plant in southern France handles this process. Depleted uranium can also be recycled.

96% of spent fuel can be recycled to produce new fuels

France’s decision in the 1980s to recycle spent fuel to produce MOX was part of the country’s national energy policy. It reduces consumption of natural uranium resources and limits the volume of final radioactive waste to be stored.

All transport takes place in sealed containers that are specially adapted to the materials being transported and the associated hazards. Transport is subject to very stringent French and international rules and is overseen by the Nuclear Safety Authority and the public authorities.